Introduction to XTools Laser Machines

In the world of manufacturing and craftsmanship, precision is everything. Imagine a tool that can cut through materials with surgical accuracy, elevating your projects to new heights. Enter XTools laser machines—an innovative solution designed for creators who demand nothing less than perfection. These advanced devices are revolutionizing how we approach design and production, providing unmatched precision across various applications.

Whether you’re a seasoned professional or an enthusiastic hobbyist, understanding the technology behind XTools laser machines can open doors to endless possibilities. Join us as we delve into the intricacies of these remarkable tools and explore how they are changing the landscape of modern fabrication.

Welcome to the world of precision, where technology meets creativity. XTools laser machines are at the forefront of this revolution, offering remarkable solutions for enthusiasts and professionals alike. Imagine transforming raw materials into intricate designs with unparalleled accuracy. Whether you’re a craftsman, an artist, or simply curious about the capabilities of modern technology, these machines unlock endless possibilities.

With advancements in laser cutting and engraving technologies, XTools has redefined what it means to work with precision tools. From personalized gifts to industrial applications, their machines cater to diverse needs while maintaining exceptional quality. Get ready to dive deeper into how these innovative devices shape industries and empower creators around the globe!

Advancements in Precision Technology

The world of laser technology is constantly evolving, and precision has reached new heights. Breakthroughs in optics and sensor technologies have transformed how laser machines operate.

Advanced algorithms now drive accuracy to levels previously thought impossible. These smart systems analyze data in real-time, allowing for quick adjustments during operation. This means fewer errors and higher-quality outputs.

Furthermore, developments in materials science have led to stronger, lighter components that enhance performance without sacrificing durability. Manufacturers are now deploying high-resolution optics that focus beams with pinpoint accuracy.

Automation plays a crucial role as well. Integrated software can streamline workflows, ensuring consistency across various projects. The combination of these innovations paves the way for industries to achieve remarkable results with every cut or engraving made by XTools machines.

Benefits of Using XTools Laser Machines

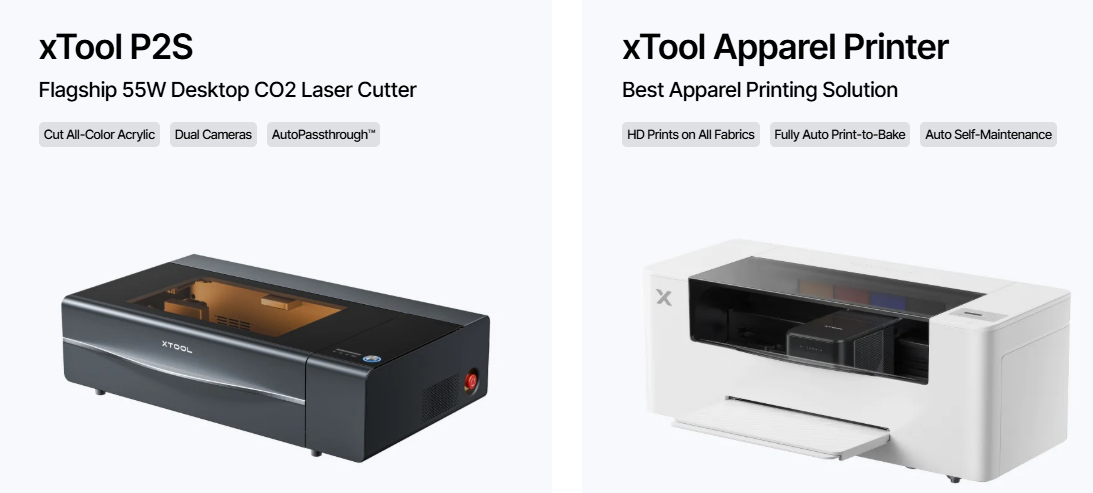

XTools laser machines offer remarkable versatility, catering to various industries. Their precision cuts and engravings ensure that every project meets the highest standards. This level of accuracy minimizes waste, leading to cost savings over time.

Speed is another significant advantage. XTools lasers operate efficiently, allowing businesses to increase productivity without sacrificing quality. Whether it’s for small prototypes or large-scale productions, these machines handle tasks swiftly.

User-friendly interfaces make operation straightforward. Even those new to laser technology can quickly adapt and start creating impressive projects without extensive training.

Additionally, XTools machines are designed with durability in mind. Investing in robust equipment means less downtime and more reliability in everyday operations.

The ability to customize designs opens up endless creative possibilities. This flexibility empowers users to experiment freely and innovate their offerings in a competitive market.

Applications of XTools Laser Machines

XTools laser machines have carved a niche across various industries. They are not just tools; they are game-changers in production and creativity.

In manufacturing, these machines excel at cutting and engraving materials like wood, acrylic, and metal with precision. This capability allows companies to produce intricate designs that stand out in the market.

Artisans also benefit from the technology. Artists use XTools lasers to create detailed artwork or personalized items that captivate customers. The customization options are nearly limitless.

Moreover, educational institutions employ these machines for teaching purposes. Students can explore design principles while working on real-world projects using advanced technology.

From signage creation to prototyping new products, XTools laser machines continue to expand their reach into diverse fields, proving essential for innovation-driven businesses.

Customer Reviews and Testimonials

Customer experiences with XTools laser machines showcase the remarkable impact of precision technology. Users frequently highlight their ease of use, even for those new to laser cutting and engraving.

One customer shared how the accuracy of their XTool machine transformed their small business. They marveled at how quickly they could produce detailed designs without sacrificing quality.

Another review spoke to the machine’s reliability during long hours of operation. Professionals appreciate that they can count on consistent performance, which is vital in meeting tight deadlines.

Beyond functionality, many users have noted exceptional customer support from XTools. Prompt assistance and helpful resources make a big difference when navigating any challenges.

These testimonials reflect an engaged community eager to share success stories. The positive feedback not only underscores product effectiveness but also fosters trust among potential buyers exploring this advanced technology.

Future Possibilities for XTools Technology

The future of XTools technology is brimming with potential. As industries evolve, so too will the capabilities of laser machines.

Imagine integrating artificial intelligence for real-time adjustments during cutting or engraving processes. This could enhance precision even further, adapting to various materials on-the-fly.

Additionally, advancements in materials science may lead to lasers that can work with previously unmanageable substances. Think about intricate designs carved into metals that were once deemed impossible.

Sustainability will also play a crucial role. Future laser machines might utilize energy-efficient systems or eco-friendly materials to minimize environmental impact without compromising quality.

Collaboration across sectors could spark innovative applications as well. From art installations to medical device manufacturing, the possibilities are vast and exciting.

As these technologies progress, we’re likely to see XTools at the forefront of new solutions tailored for diverse needs. The journey has only just begun.

Conclusion

The landscape of laser technology is evolving rapidly, and XTools stands at the forefront of this transformation. With cutting-edge advancements in precision technology, these machines are redefining what’s possible in various industries. The benefits they offer—such as enhanced accuracy and versatility—are making them indispensable tools for businesses.

From crafting intricate designs to manufacturing complex components, the applications for XTools Laser Machines are vast. Many users have shared positive experiences, praising the reliability and exceptional results produced by these devices. Their feedback underscores how integral these machines have become in everyday operations.

Looking ahead, one can only imagine where innovations will take us next. As technology continues to advance, it opens new doors for creativity and efficiency across multiple sectors. Exciting possibilities await those ready to harness the power of XTools Laser Machines—a true testament to the future of precision engineering.

The advancements in laser technology have significantly transformed various industries. XTools Laser Machines stand out by offering innovative precision that meets diverse needs. From cutting to engraving, these machines are designed for accuracy and efficiency.

Customers praise the reliability and versatility of XTools products. Many report enhanced productivity and superior results in their projects. The positive feedback highlights how these machines can elevate a business’s capabilities.

Looking ahead, the future of XTools technology promises even greater innovations. As industries evolve, so will the tools that power them, ensuring that precision remains at the forefront of manufacturing processes.

Embracing this technology opens new avenues for creativity and functionality across sectors like woodworking, metal fabrication, and custom design work. Investing in an XTools Laser Machine could be a game-changer for businesses aiming to stay competitive in today’s fast-paced market.