Introduction to the XTools Laser Cutter and Engraver

Looking to elevate your creative projects? The XTools Laser Cutter and Engraver is a game-changer. Whether you’re crafting personalized gifts or creating intricate designs for your business, this powerful machine opens up a world of possibilities. But like any tool, getting the most out of it requires some know-how. From understanding its capabilities to mastering best practices, we’re here to guide you through maximizing efficiency with your XTools laser cutter and engraver. Let’s dive into what makes this innovative gadget an essential part of your workshop!

Are you ready to unleash your creativity with the XTools Laser Cutter and Engraver? This innovative machine is more than just a tool; it’s a gateway to endless possibilities. Whether you’re crafting intricate designs or engraving personalized gifts, mastering this technology can transform your projects from ordinary to extraordinary.

Imagine cutting through wood, acrylic, leather, and even metal with precision. The XTools laser cutter allows you to bring your visions to life effortlessly. But like any powerful tool, knowing how to maximize its potential is key.

Let’s dive into best practices that will elevate your experience and make every cut and engraving count!

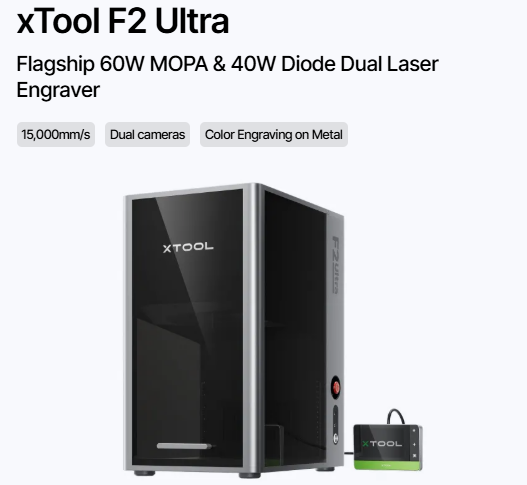

Understanding the Capabilities of Your Machine

Your XTools laser cutter and engraver is a powerhouse of creativity. It’s designed to handle an array of materials, from wood to acrylic and leather. Understanding these capabilities lets you unlock its full potential.

The machine’s precision is remarkable. It can achieve intricate designs with ease, allowing for both delicate engraving and robust cutting tasks. This versatility makes it suitable for various projects, whether you’re crafting personalized gifts or producing prototypes.

Speed settings are adjustable too. You can tailor the speed based on material type and thickness, ensuring optimal results every time you operate it.

Moreover, software compatibility enhances functionality. With user-friendly design programs, transferring your ideas into reality becomes seamless.

Taking the time to explore all these features will elevate your craftsmanship while expanding your creative horizons significantly. Embrace experimentation as you discover what this powerful tool can truly accomplish!

Preparing Your Design for Cutting and Engraving

Preparing your design is a crucial step in achieving the best results with your XTools laser cutter and engraver. Start by ensuring that your artwork is in a compatible format, such as SVG or DXF. These formats retain the necessary detail for precise cutting and engraving.

Next, scale your design to fit within the machine’s working area. Keep an eye on dimensions to avoid surprises during production. A good rule of thumb is to leave some margin around edges.

Make sure to differentiate between cut lines and engrave areas using color coding or line thickness adjustments. This clarity will guide the machine accurately through each process.

Perform a test run on scrap material before diving into your main project. This simple step can save time and materials while fine-tuning settings like speed and power levels for optimal performance.

Preparing your design correctly is crucial for achieving the best results with your XTools laser cutter and engraver. Start by choosing a software that aligns well with your machine’s requirements. Programs like Adobe Illustrator, CorelDRAW, or free options such as Inkscape can help you create intricate designs.

When designing, make sure to keep in mind the material you’ll be working with. Each material has its own settings regarding speed and power. A detailed understanding of these specifications can prevent frustrating errors later on.

Next, consider using vector graphics for cutting tasks since they provide more precise lines than raster images. For engraving, high-resolution images are essential; this will ensure clarity in finer details during the process.

Once your design is finalized, double-check dimensions and alignments before sending it to the cutter. Many users find it helpful to do a test run on scrap materials to fine-tune settings without wasting precious stock.

Choosing the Right Materials for Your Project

Selecting the right materials is crucial for achieving optimal results with your XTools laser cutter and engraver. Different materials behave uniquely when exposed to laser technology, which can impact both quality and efficiency.

Start by considering common options like wood, acrylic, leather, and paper. Each material offers distinct aesthetics and functional properties. For instance, plywood can deliver a warm finish while acrylic provides vibrant colors that catch the eye.

Thickness also matters. Thicker materials require more power but may yield cleaner cuts if adjusted correctly. Experimentation will help you understand how different thicknesses perform with your machine settings.

Don’t forget about coatings or finishes on materials. Some treatments might release harmful fumes during cutting or engraving; always check compatibility before starting a project.

Sourcing high-quality materials ensures better outcomes in terms of detail and durability. Trustworthy suppliers often provide specifications that guide you in making informed choices.

Selecting the right materials for your project is essential when working with the XTools laser cutter and engraver. The material you choose can significantly impact both the quality of your final product and the efficiency of your workflow.

Start by considering what kind of project you are undertaking. Wood, acrylic, leather, fabric, and metal all have different properties that can affect cutting speeds and engraving details. For instance, wood is generally forgiving; it cuts smoothly but may require different settings depending on its density. Acrylic offers vibrant colors and a clean finish but can be prone to melting if not set correctly.

When experimenting with new materials, always do a test run first. This will give you insight into how well they respond to cutting or engraving without risking your main workpiece. Each material requires specific power levels and speed adjustments for optimal results—small tweaks can make a big difference in precision.

Don’t forget about safety too! Some materials release harmful fumes when cut or engraved. Always operate in a well-ventilated area or use an appropriate filtration system to keep yourself safe while working on ambitious projects.

Sourcing high-quality materials pays off in spades. Investing time in finding reliable suppliers ensures that you’ll obtain consistent results every time you fire up your XTools machine.

The blend of creativity with thoughtful choices leads to impressive finishes that stand out from ordinary projects—elevating each piece into something truly unique.

Best Practices for Operating and Maintaining Your XTools Machine

Maintaining your XTools laser cutter and engraver is essential for optimal performance. Regular cleaning keeps the optics clear and prevents debris buildup, which can affect precision.

Always check the lens and mirrors before starting a new project. A quick inspection can save you time and ensure clean cuts. Use appropriate cleaning solutions to avoid damaging sensitive components.

Calibration is crucial too. Make it a habit to calibrate your machine periodically for consistent results across various materials.

Safety should not be overlooked either. Always wear protective eyewear when operating your machine, even during routine tasks like maintenance.

Keep an eye on software updates from XTools. These upgrades often introduce enhancements that improve efficiency or expand capabilities, ensuring you get the most out of your investment in this powerful tool.

Creative Applications of the XTools Laser Cutter and Engraver

The XTools Laser Cutter and Engraver opens up a world of creativity. Artists can transform their visions into stunning 3D pieces, using intricate designs that come to life through precise cuts.

Crafters are also embracing this technology for personalized gifts. Imagine custom engraved jewelry or bespoke home decor items that leave a lasting impression on friends and family.

Businesses find immense value in branding opportunities. From signage to promotional merchandise, the ability to engrave logos onto various materials elevates brand identity.

Educational institutions use laser cutters for hands-on learning experiences. Students explore engineering concepts by designing and creating products from scratch, fostering innovation right in the classroom.

Even hobbyists have found joy in repurposing everyday objects with unique engravings or creative cuts, breathing new life into discarded items while showcasing individuality. The possibilities truly are endless!

Conclusion

Maximizing your efficiency with the XTools Laser Cutter and Engraver opens a world of creative possibilities. By understanding its capabilities, preparing your designs meticulously, and selecting the right materials, you can achieve remarkable results.

Operating and maintaining your machine properly ensures longevity and optimal performance. The potential applications for this technology are endless—from intricate engravings to precise cuts in various mediums.

Embracing these best practices will not only enhance your projects but also make the entire process more enjoyable. With each creation, you’ll discover new ways to push boundaries and unlock your artistic vision using this powerful tool.

Maximizing the efficiency of your XTools Laser Cutter and Engraver can transform your creativity into reality. By understanding the capabilities of your machine, you set a solid foundation for every project. Preparing your designs accurately ensures that what you envision becomes what you create.

Choosing appropriate materials is crucial for achieving high-quality results. The right choice not only affects the final appearance but also impacts how well the machine processes each cut or engraving. Embracing best practices in operation and maintenance will prolong the life of your equipment while optimizing performance.

Exploring creative applications opens doors to endless possibilities. Whether it’s personalized gifts or intricate decor, let your imagination run wild with this powerful tool at hand. With these insights, you’re now equipped to take full advantage of your XTools Laser Cutter and Engraver!